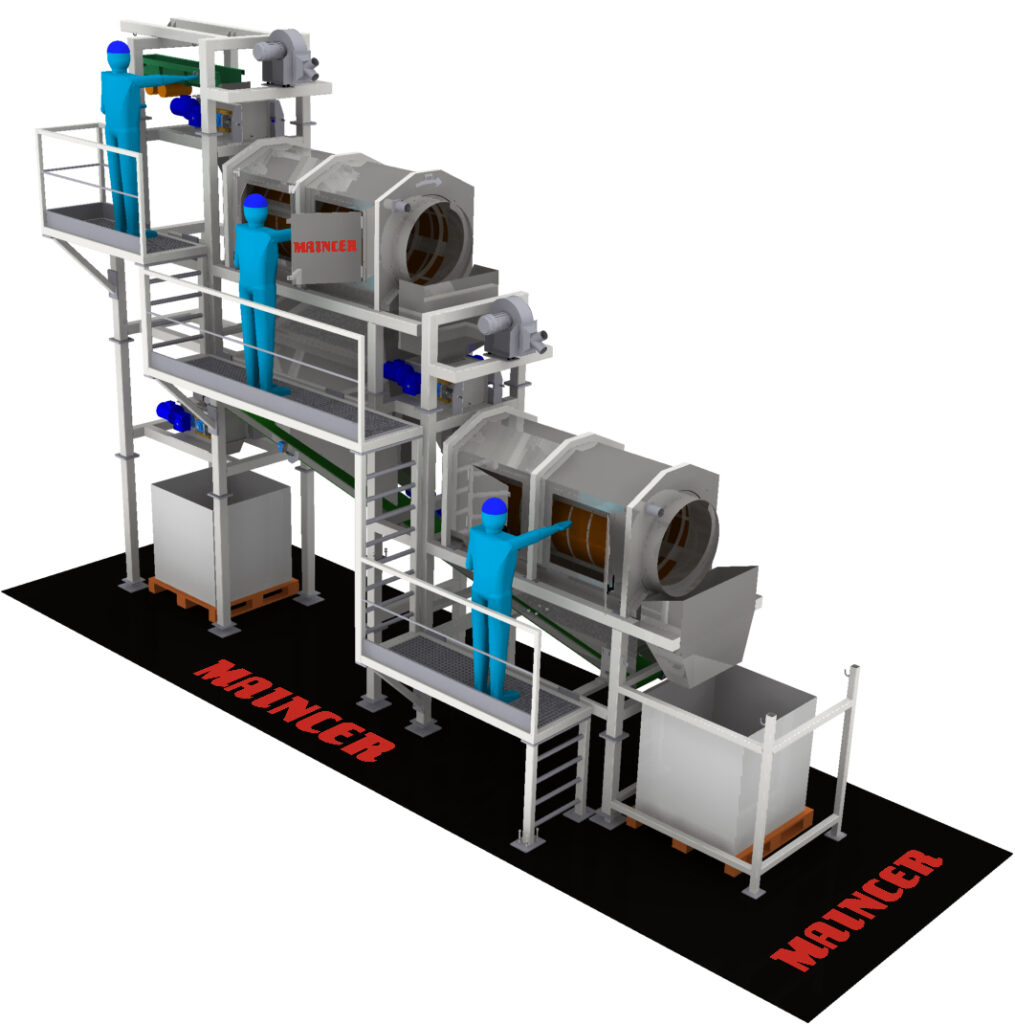

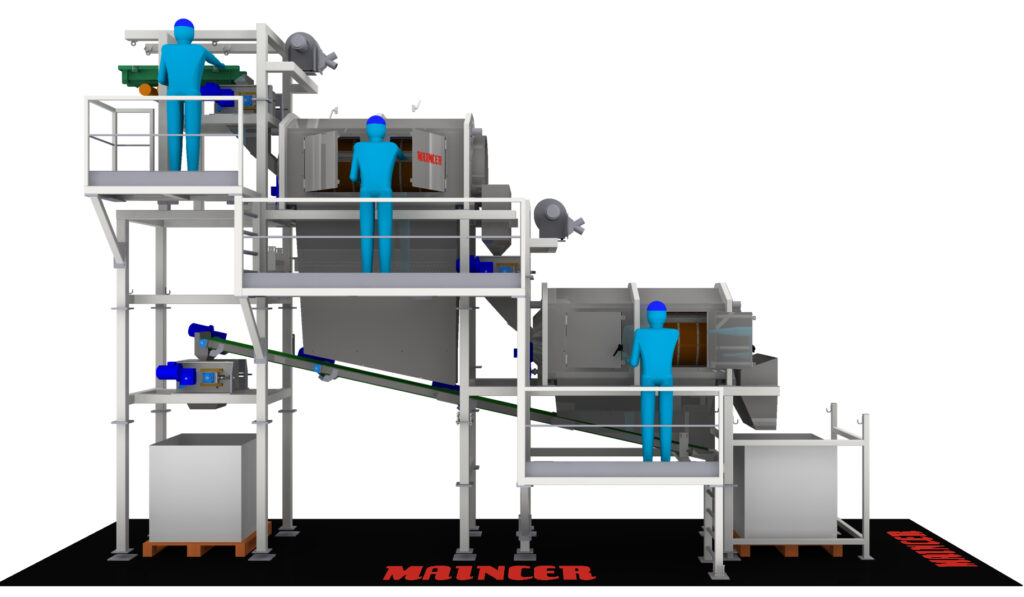

Eggshell recycler

The EGGSHELL RECYCLER from Maincer is a system for mechanically separating the organic from the inorganic part of the eggshell. The whole eggshell is fed into the machine and after the process two subproducts are obtained: in one side the membrane and in the other side calcium bio-carbonate (CaCo3).

The system is composed by:

- Feeding tray

- Grinder 1

- Sieve 1

- Mill 2

- Sieve 2

- Accumulation tank / big-bag for the membrane

- Calcium bio-carbonate recovery belt.

- Mill 3

- Deposit / big-bag accumulation of calcium bio-carbonate.

Productivity > 10T/day

The tested productivity of the machine is more than 10 tons per day in continuous cycle (24 hours). From these 10Tn, 7.5Tn are Bio-CaCo3 and 2.5Tn are a mixture of Bio-CaCo3 + membrane.

Conclusions

Once the machine has been installed and the operating variables (separation and speed of the rollers and speed of the rotary sieve) have been adjusted. The following conclusions can be drawn:

- High membrane removal is being achieved with the prototype.

- Around 75% total recovery (on a dry basis) is achieved.

The bio-CaCO3 obtained is almost membrane-free, so that both parts (membrane and bio-CaCO3 are usable in other processes or industries.

LIFE EGGSHELLENCE project website https://www.lifeeggshellence.eu/

2045

2045

2043

2043